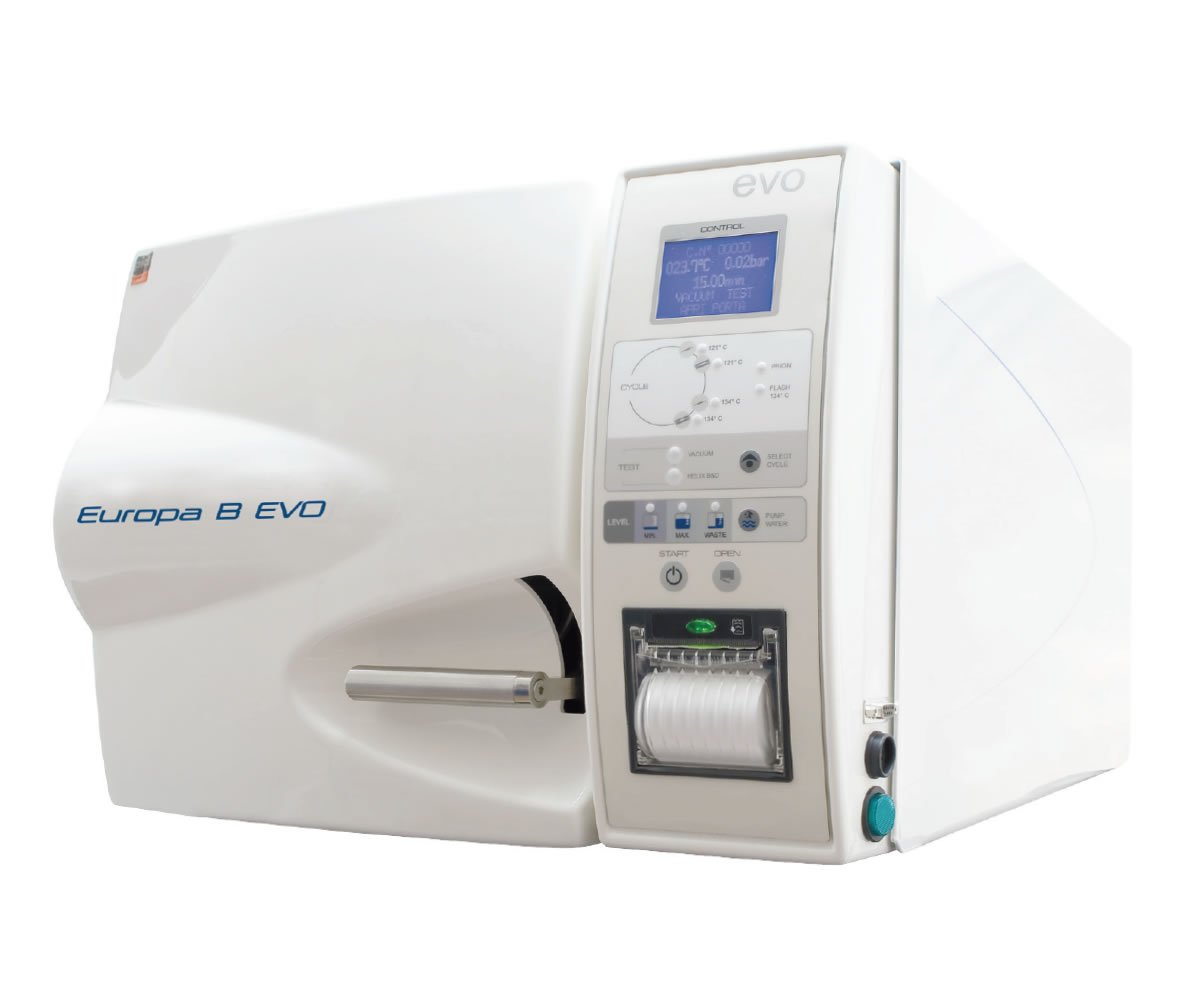

Description

RT 92 has a circular chamber in treated AISI 304 stainless steel. Maximum load per cycle is 5 kg. 3 door-mounted safety devices: electromagnet, electric, dynamic. Control card integrated into the control panel. Graphic display. Automatic air pressure alignment system. Water refueling by pump and automatic shut-off when tank is full. Door gasket for maximum service life. Control panel with connections and automatic water filling and draining on the rear panel. Integrated forced ventilation system. Tray holder with protection to prevent contact between load and chamber. RT92 features a fractional vacuum system. This system alternates between negative and positive pressure phases. It is activated at the start of each sterilization cycle and ensures complete elimination of air pockets from all types of material, including hollow and porous materials. Pre-set temperatures: The programmed temperatures for our autoclave cycles are 134°C and 121°C. Cycles at 134°C are normally used for sterilizing solid and ferrous materials. Cycles at 121°C are normally used to sterilize thermoplastics, fabrics and delicate materials. Fully automatic cycles: all cycles are fully automatic. Each phase (vacuum, preheating, exposure time, drying) is controlled, assisted and managed automatically by a latest-generation board equipped with a powerful microprocessor. No human intervention is required during cycles. Wide choice of operating cycles: RT92 features: 1 sterilization cycle at 134°C for loose and wrapped materials, 1 sterilization cycle at 121°C for loose and wrapped materials, 1 "flash" sterilization cycle for rapid cycles, 1 "prion" sterilization cycle specially designed for Creutzfeldt-Jakob disease - cycles with no operator intervention and automatic stop. All sterilization cycles have an automatic function which, when the operator is absent at the end of the cycle, starts an anti-condensation process and causes automatic shutdown. This system saves money and enhances machine safety. Test cycles: RT 92 includes test cycles to periodically check the unit's physical and functional systems: Helix test to assess vacuum capacity in porous bodies, Bowie & Dick test to assess vacuum capacity in bodies, Vacuum test to assess vacuum holding capacity. ACCESSORIES - Aluminum trays: No. 4. TECHNICAL CHARACTERISTICS - Built-in printer: Yes. Chamber dimensions: mm Ø 245 - 318. Chamber capacity: lt 18. External dimensions mm 510x590x390(H). Load classification: Type B. Weight: kg 63. Power: W 1500. Voltage: 230 V - 50/60 hz./*54745756836*/